Custom solutions for specific parts

Ensure a result without marks on all types of metals

Traceability management and NADCAP compliance

ATEX special machines

Meets surface tension criteria

Zero-discharge solution by treatment of the waste

Our machines will clean your parts in different steps of your process :

Before non-destructive test (dye penetrant)

Before heat treatment

Before dimensional check

In-process operation

Final wash

The components of the aeronautic business are made of a wide variety of materials such as inconel, titanium, aluminium and superalloys.

Like the downstream process, these metals should be considered in the choice of the cleaning method to be used: chlorinated solvents, aqueous solution, hydrocarbons, micro-emulsion…

Surface Alliance machines in the aeronautic business are equipped with systems for continuous control of the process parameters in connection with the PLC. This system is allowing a report editing after each cycle and the data recording offering a standardized approach.

For this purpose, each sensors working condition is essential (Level, Temperature, Pressure, pH, Conductivity…).

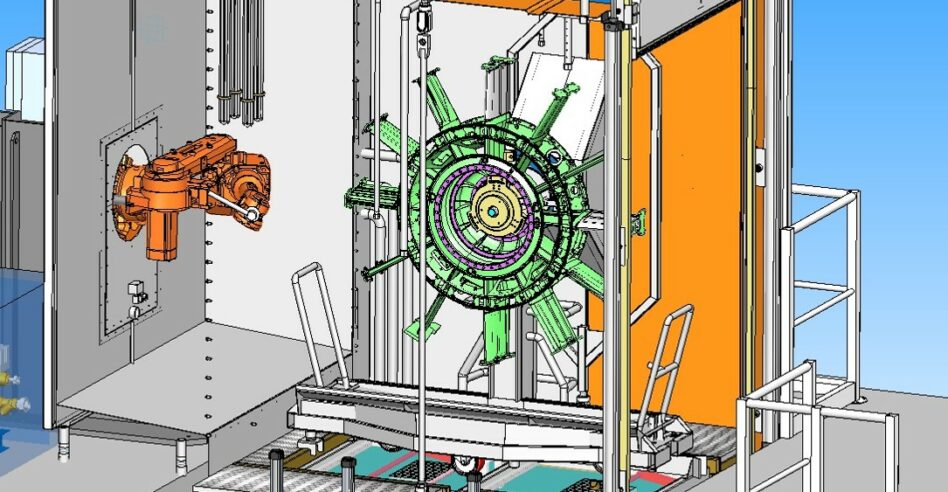

The tooling design and the customized palets for parts to be processed is one of strength of Surface Alliance. The part positioning for the cleaning and drying operation is critical to obtain high cleanliness results.

To make these results reliable, completed cleaning process automation with machine IQ, or even automatic loading/unloading of parts or palets via peripheral equipment (robots, conveyors, loaders, lifting tables…) allow to reduce manual operations.

The cleaning of complex and sensitive parts such as drive gear housings requires that the cleaning fluid be identical or have properties close to the fuel which will circulate in its circuits (kerosene, MEK, Diestone…).

This type of cleaning equipment operating in an explosive environment (ATEX) is an integral part of Surface Alliance know-how.

Equipped with several rinsing tanks to achieve the desired cleanliness of the component, a continuous control of the conductivity of the baths from 0 to 200 µS allows to ensure the repeatability of the cleanliness requirement.

For each of his machines, Surface Alliance puts in place devices for filtration and for washing/rinse fluids reprocessing for a zero-emission solution.

Bath transfer

Reverse cascade

Multiple filtration thresholds

Purified water production system

Regeneration by resins ion exchange

Oil skimmer

Evaporator with vapors mechanical compression

Centrifuges

Some examples of parts and components cleaned in the aeronautic industry :

Machining toolings

Gear housings and housings

Rectifiers

Tube and ramps

Ferrules

Carbon disc

Turbine disc

Structural components

Drilling grids and templates

Drive shafts

and much more…

Solve our customer cleanliness issues by finding out the best Industrial parts washers. Our industrial parts cleaning machines can be perfectly adapted to your production lines.

Depending on your parts, contaminants and cleanliness requirements, together we can define the most appropriate process for cleaning your industrial parts, using our machines and different technologies.

Discover our cleaning technologies adapted to each of the sectors in which we operate. From the automotive sector to aeronautics and railways. We offer parts cleaning solutions for the medical, oil and general industrial sectors.

Mark free degreasing on a MecanoLav MB machine for aeronautic straighteners after a dye penetrant inspection